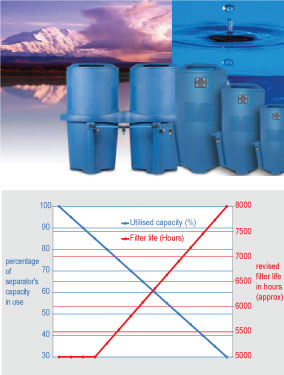

Available exclusively from SEPURA, and probably the world’s largest capacity condensate cleaner, SEPURA 3500 & 7000 are uncompromising and reliable allies in the fight against pollution and the battle for legislative compliance.

• Unique and patented environmentally clean re-cycled ‘filter’ medium

• No moving parts

• No power consumption

• No maintenance required until service exchange is due

• Up to 2 years between services at capacities of 3500 or 7000 cfm

(100 or 200 m3/min)

• 5000 or 10000 cfm (140 or 285 m3/min) possible depending upon

site conditions

For too long, the large user of compressed air has been offered a difficult choice between condensate cleaning technologies; emulsion splitters or multiple ‘carbon bag’ separators.

If a splitter is chosen only for its large capacity, the penalty is high initial cost, complexity and high maintenance. Multiple small separators are notoriously tricky to balance on installation, which results in poor performance, unreliability and expensive waste.

SEPURA 3500 & 7000 offer the best of both worlds. High capacity, simple installation, low running costs and pure performance.

SEPURA 3500 & 7000 can even handle stable emulsions—condensate samples are required to determine performance and capacity.

General description

These large SEPURA cleaners are designed to remove oil from compressed air condensate down to levels that are sufficiently low that discharge of treated condensate to the foul sewer is allowed.

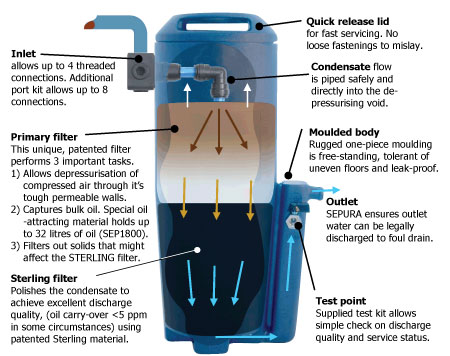

Condensate discharged from the compressed air system (together with any compressed air also released) is fed into the substantial pressure relief chamber. Here the energy of discharge is removed, allowing calm entry of the condensate into the filter chamber.

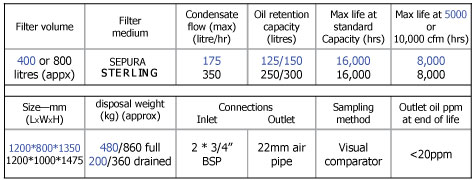

The chamber is built from a standard and inexpensive IBC (intermediate bulk container) with a total volume of approx 600 or 1000 litres (model dependent). 80% of this volume is filled with SEPURA STERLING, a patented oil adsorbing material with extremely high oil capacity and the capability to clean condensate down to <5 mg/ml (5ppm) oil content. The filter bed is submerged in condensate during operation.

A drainage channel collects cleaned condensate at the base of the filter bed, feeding it out through simple push-fit pipe-work, where the outlet position determines the height of water within the filter chamber. A vertical extension pipe ensures siphoning does not occur in the discharge pipe.

A ‘tee’ piece and tap provide an outlet condition monitoring point.

At the end of its service life, the IBC complete with oil residues is taken away for disposal at a registered site. The pressure relief chamber and discharge pipe-work are retained for connection to a new container with clean STERLING material.