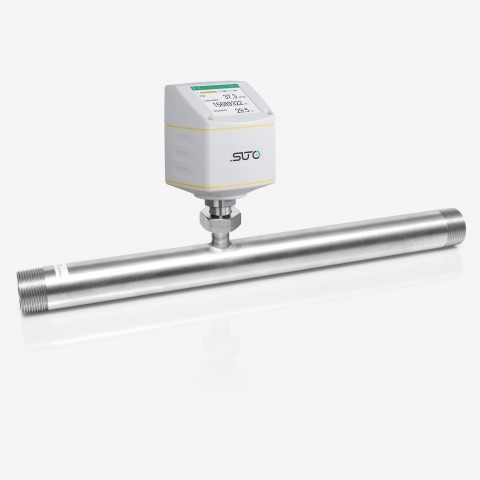

- Thermal mass-flow meter

- Accuracy down to 1.5% and Optional 1%

- Installation under pressure (ball valve required) – HOT installation

- Choice between 3 range models (Standard, Max and High range)

- Available with or without integrated display on the meter

- Output : Modbus or 4-20mA, Pulse, Bluetooth

- Configuration as stationary or portable instrument by user possible

- Pipe Size : 1” to 12” or more upon request

More info : http://www.suto-itec.com/

A choice of four different process connections (threat / flange)

- Thermal mass-flow meter

- Accuracy down to 1.5% or Optional 1%

- Easy and cost-efficient installation

- Available with or without integrated display on the meter

- Output : Modbus or 4-20mA, Pulse and Bluetooth

- Configuration as stationary or portable instrument by user possible

- Pipe size : 1” to 3”

- Threaded and Flange

More info : http://www.suto-itec.com/

- Thermal mass-flow meter

- Preferred choice for demanding operational conditions

- Measuring compressed air and gases

- Ex-proof version available as option

- Range : 1/2” to 12” or bigger upon request

More info : http://www.suto-itec.com/

- Thermal mass-flow meter

- Preferred choice for demanding operational conditions

- Measuring compressed air and gases

- Ex-proof version available as option

- Pipe size L 1/4” to 3”

- Threaded and Flange

More info : http://www.suto-itec.com/

- Flow and consumption measurement in wet air or high mass flow / velocity applications

- Measurement at compressor outlet possible

- Insertion type, easy installation under pressure through ball valve possible

- High temperature applications up to 200 °C

- No mechanical wear parts

- All parts which are in contact with flow medium are made of stainless steel

More info : http://www.suto-itec.com/

- New SUTO-iTEC sensor technology

- Version with integrated pressure measurement

- Various output versions available: 1 x 4…20 mA, 2 x 4…20 mA, RS-485 (Modbus), 4…20 mA loop powered

More info : http://www.suto-itec.com/

- Newly developed sensor for improved signal integrity and stability

- Ideal for dew point measurement at desiccant dryers

- Compact design for narrow installation conditions

More info : http://www.suto-itec.com/

- cost-efficient solution for monitoring of refrigeration dryers

- long term stable sensor

- IP 65 casing for rough operational conditions

More info : http://www.suto-itec.com/

- complete measurement device with sensor, display and alarm outlet

- long term stable sensor

- IP 65 casing for rough operational conditions

More info : http://www.suto-itec.com/

- Measuring with one device

- dew point, temperature, pressure

- extremely quick results

- On-site printing and data logging feature

- touch screen interface

More info : http://www.suto-itec.com/

- measuring, display and logging of data

- for all relevant parameter of a compressed air system: flow, dew point, pressure, temperature, power consumption, compressor status, etc.

More info : http://www.suto-itec.com/

- Ideal data logger for Energy Management according to ISO 50001 and Compressed Air Audits according to ISO 11011

- flexible, safe, efficient

- easy to use

- Works with all type of SUTO Sensors, analogue sensors and Third party sensor with modbus

More info : http://www.suto-itec.com/

- Client access through web browser (PC, tablet, HMI terminal)

- Scalable customizable solution

- Communication with field devices through Modbus/TCP or Modbus/RTU

- Multi language support

More info : http://www.suto-itec.com/

- Measures residual oil contents in compressed air and other gases

- Can be used for permanent or in portable applications

- Measures down to 0.001 mg/m³

- Easy connection through sampling hose and quick connect

More info : http://www.suto-itec.com/

- Easy connection to compressed air through 6 mm quick-connector

- Can be used as portable as well as stationary instrument

- Particle sizes from 0.1 … 5.0 μm (depending on model)

More info : http://www.suto-itec.com/

The SUTO S 415 and S 418 thermal mass flow meters offer gas flow and consumption measurement directly at the point of use. These highly economical units will help you improve system efficiently, while helping reduce compressed air usage and operating

costs. The S 418 is ideal for remote locations or high accuracy with its built in data logger and optional pressure sensing

• Thermal mass flow measurement, independent of pressure and temperature

• Bluetooth interface for setup and confguration

• Accuracy of 1.5% o. RDG (S 418) and 3% o. RDG (S 415)

• Output signal options: 4 … 20 mA and pulse, Modbus, M-BUS

• Simple installation, no straight pipe required

• Measures the full flow, no bypass measurement

• 4-Digit LED display

• Available in DN8, DN15, DN20, DN25 process connection G inner thread

• S 418 comes standard with integrated data logger

• Optional pressure measurement available for S 418

More info : http://www.suto-itec.com/